Nuoguard Shanghai

Let me introduce the four operating states and four key “points” of press brake:

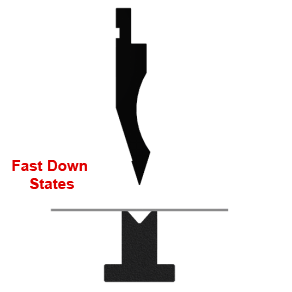

1、Fast Down States

The rapid descent of the upper beam, moving toward the speed change point, is referred to as fast down state. Although fast down cannot ensure precise positioning of the upper beam, it allows the beam to descend at a high speed, effectively improving the overall bending efficiency.

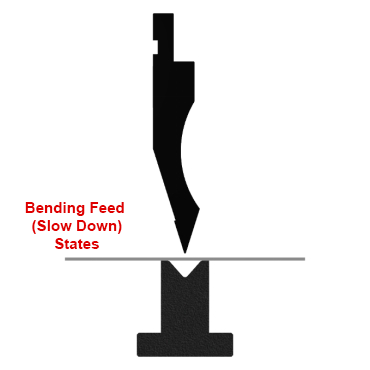

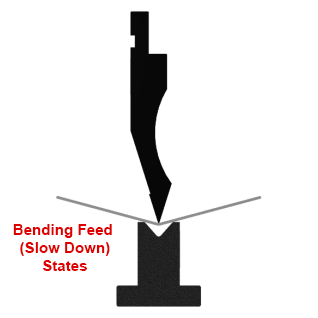

2.Bending Feed (Slow Down) States

The movement of the upper beam from the speed change point to the preset bottom dead center position (the bending forming position) is called bending feed. This is the process in which pressure is built up in the upper chamber of the cylinder to bend the workpiece. At this stage, the downward speed of the upper beam is between 0–10 mm/s. The proportional directional valve precisely controls the speed and position of the upper beam, ensuring the accuracy of its arrival at the bottom dead center and guaranteeing the forming angle of the workpiece.

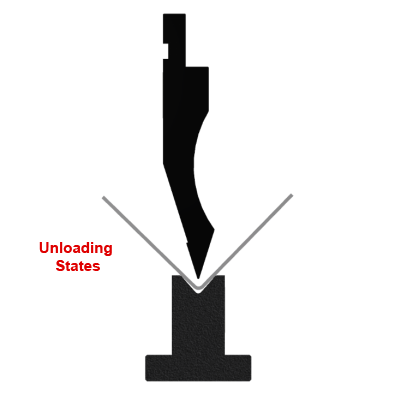

3.Unloading States

The slow upward movement of the upper beam from the bottom dead center to the preset distance value is called unloading. During the unloading process, the pressure built up in the upper chamber of the cylinder is released, while pressure is built in the lower chamber to overcome the weight of the upper beam, allowing it to rise slowly.

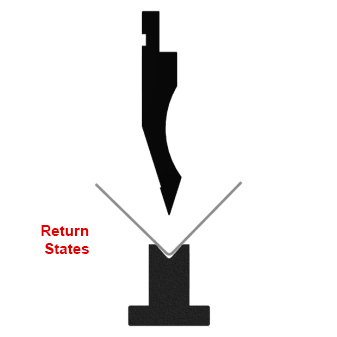

4.Return states

The rapid upward movement of the upper beam to the preset top dead center position is called return. Throughout the return process, the press brake operates in a state where the weight of the upper beam is being overcome while the beam moves at high speed, resulting in relatively high pressure within the hydraulic circuit.

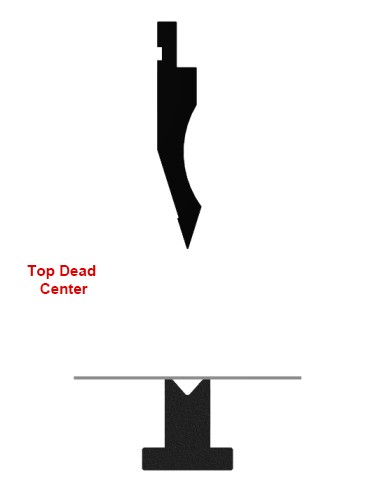

5.Top Dead Center

▪ When the cylinder piston reaches the highest limit of its travel path — that is, when the upper beam reaches its highest position — it is referred to as the maximum top dead center.

▪ After the bending cycle is completed, the position to which the upper beam returns, as set by the CNC system, is referred to as the top dead center.

6.Bottom Dead Center

When the cylinder piston reaches the lowest limit of its travel path — that is, when the upper beam reaches its lowest position — it is referred to as the maximum bottom dead center.

When the upper beam moves to the bending position set by the CNC system — the forming position for achieving the desired workpiece bending angle — it is referred to as the bottom dead center.

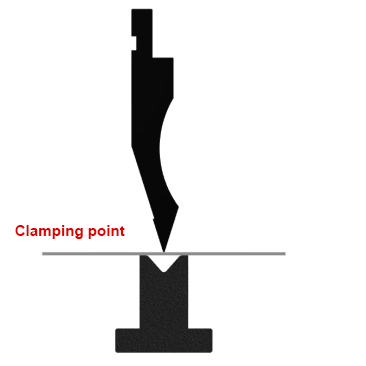

The position where the upper die makes contact with the workpiece placed on the lower die is referred to as the clamping point. At this stage, the sheet has not yet undergone deformation and is held firmly in place, preventing any movement. The clamping point is often used in applications involving backgauge auxiliary retraction or robotic bending operations.

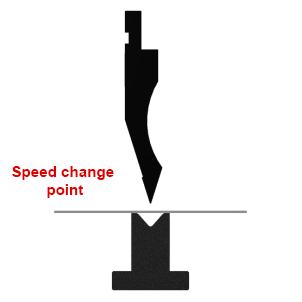

8.Speed Change Point

The position where the upper beam transitions from rapid descent to slow descent (working feed state) is referred to as the speed change point.