- Home

- About

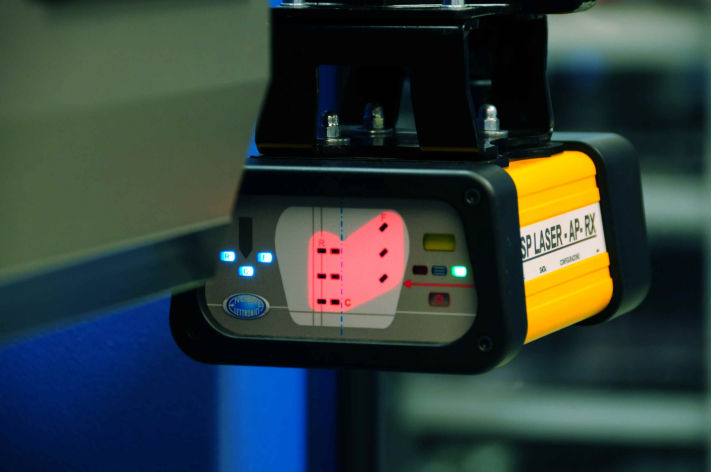

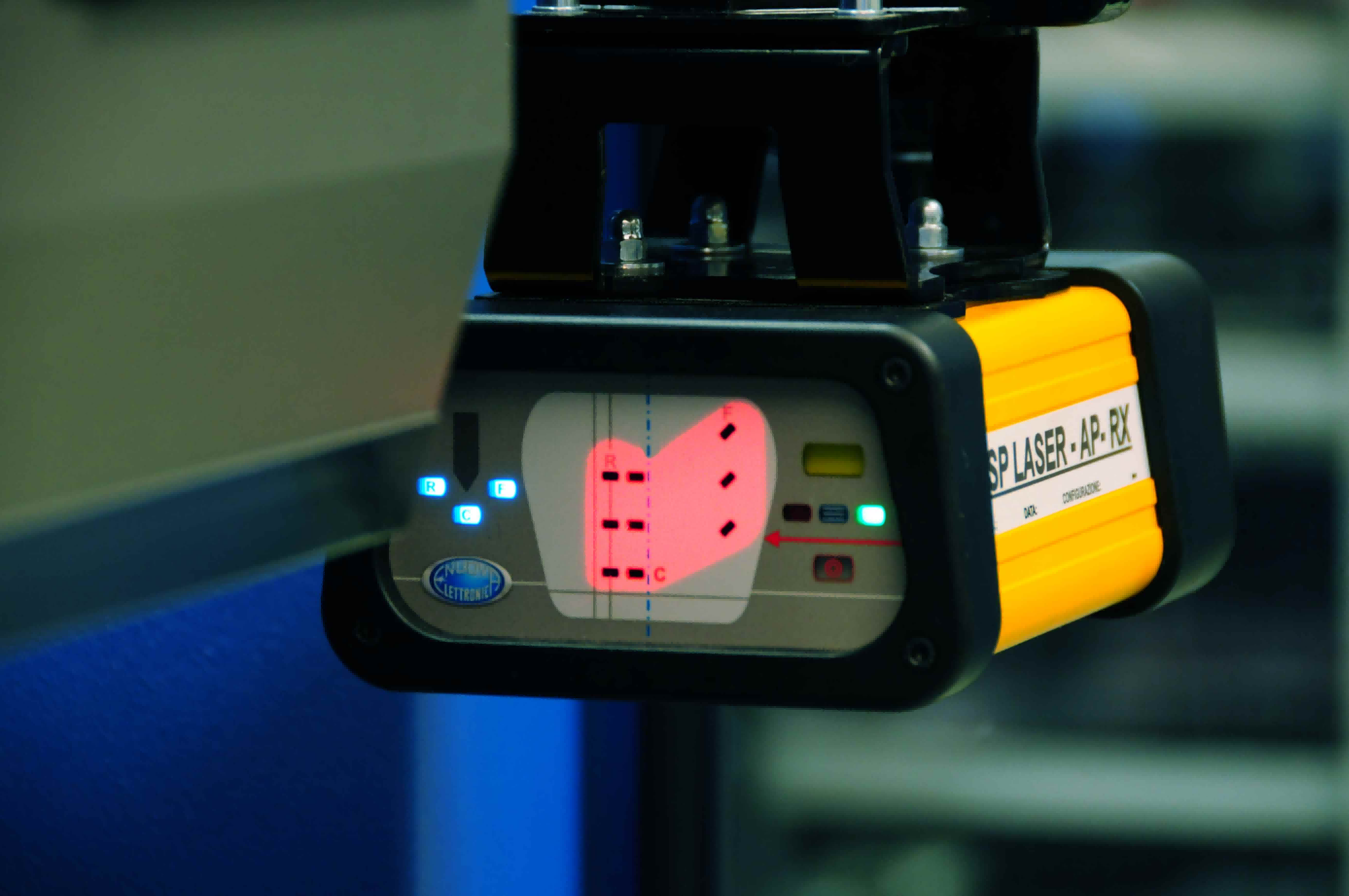

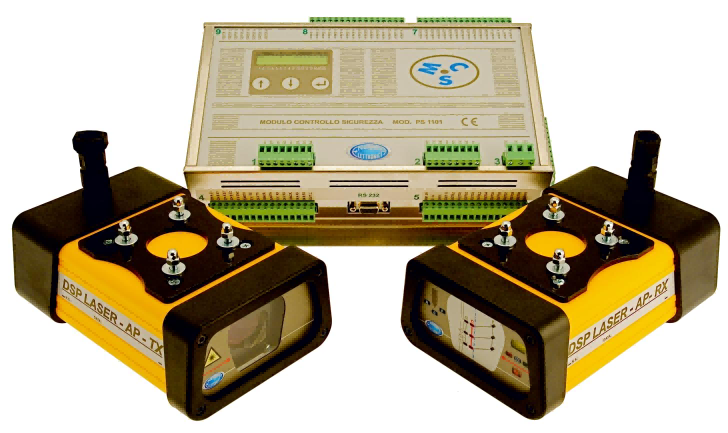

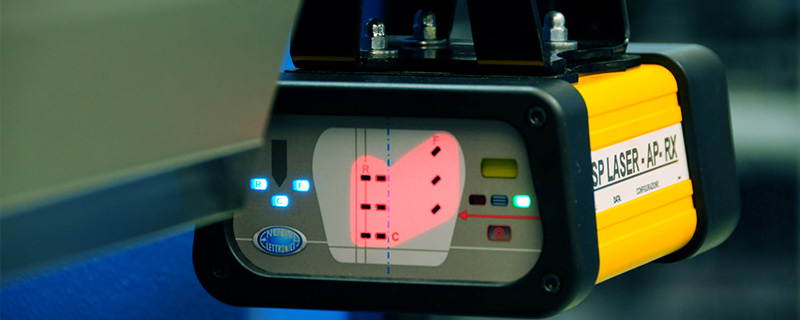

NUOVA ELETTRONICA is based in Perugia, Italy. With more than 40 years of experience in the field of press brakes safety. The company's leading product is laser safety devices , Since the year of 1979, Products and technology are among the best in the worl...

- Product

The company's leading product is laser safety devices , Since the year of 1979, Products and technology are among the best in the world. NUOVA ELETTRONICA is in the forefront of the press brake safety devices....

- Case

english description...

- News

english description...

- Custom Case

english description...

- Contact

english description...